R404a или R507. Что эффективнее?

404a vs r507. What is more efficient?

In the meantime, there is no need to know about it. ”

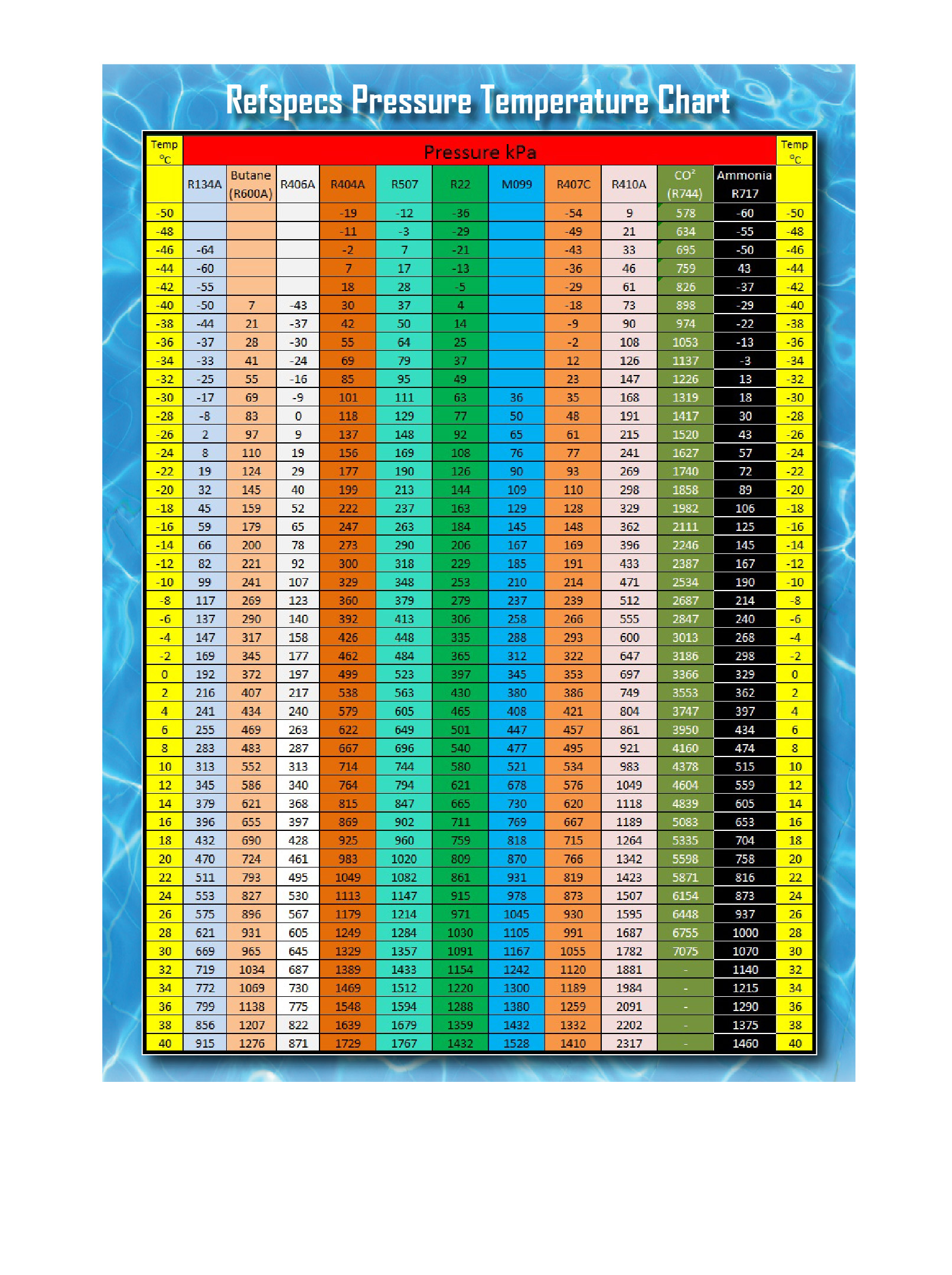

Freon R404a was developed to replace the outdated refrigerant R502, which had a greenhouse effect and depleted the ozone layer.

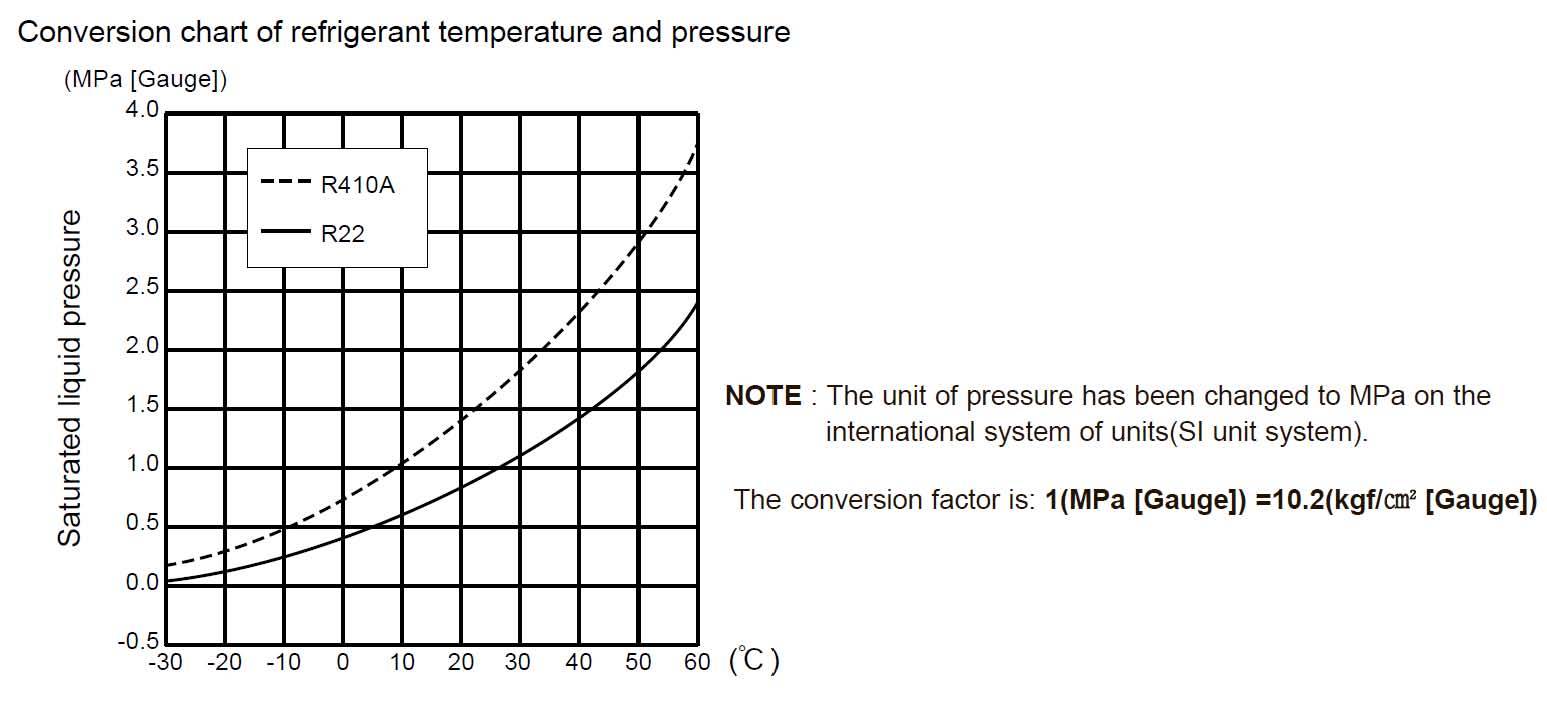

The principle of phasing out CFCs — for example, R502 — in new refrigeration systems came into force 10 years ago. The ban on the use of HCFCs (primarily R22) in new equipment has been in effect since 2004, and in 2010 it will be prohibited to service any systems that use this refrigerant.

In the meantime, hydrofluorocarbon refrigerants such as R404A and R507 are increasingly replacing obsolete refrigerants and are being adopted by almost all OEMs. However, the increasing importance of energy efficiency leads to more attention being paid to the choice of refrigerant: after all, even small changes in performance can achieve significant energy savings.

In the meantime, there is no need to know about it. ”

”

Why use HFCs?

Compounds based on hydrofluorocarbons do not deplete the ozone layer (ozone depletion potential is zero) and are extremely effective as refrigerants, therefore their use will lead to significant energy savings in the future. Moreover, when properly stored, they do not have a noticeable effect on the global warming process, which makes their use more justified from the point of view of protecting the environment. In addition, they are non-flammable, chemically resistant, non-toxic, easy to handle and compatible with many materials.

Finally, hydrofluorocarbons have good thermodynamic properties. This means that they fully meet the technical specifications and refrigeration capacity requirements for the systems under development, as well as for retrofit systems that previously used R502 refrigerant. These systems can range from small stand-alone refrigeration units to supermarket equipment and industrial process equipment.

HFCs are the best refrigerant for new systems replacing those that used R22.

In the meantime, there is no need to know about it. ”

Characteristics of R404A and R507

In the meantime, there is no need to know about it. ”

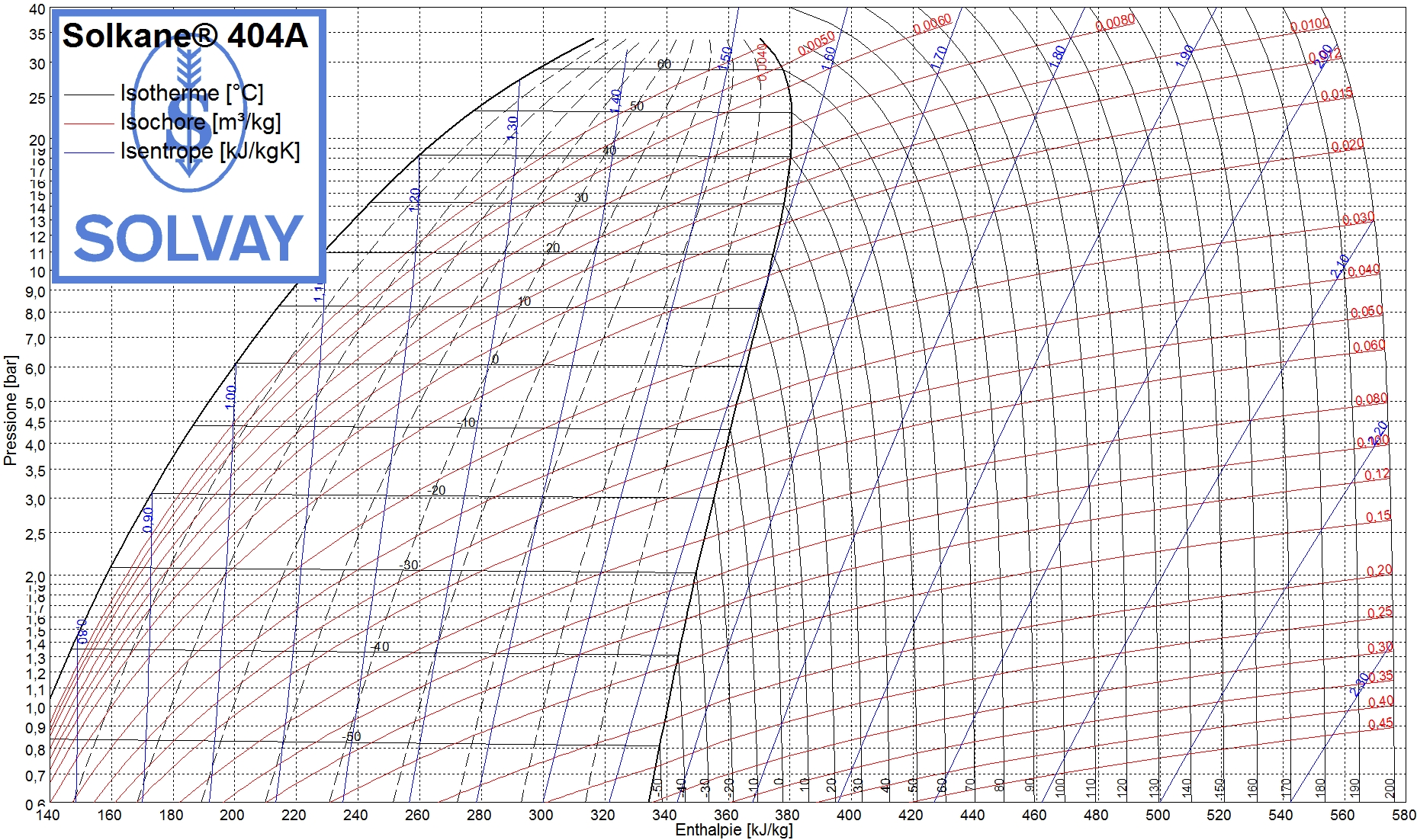

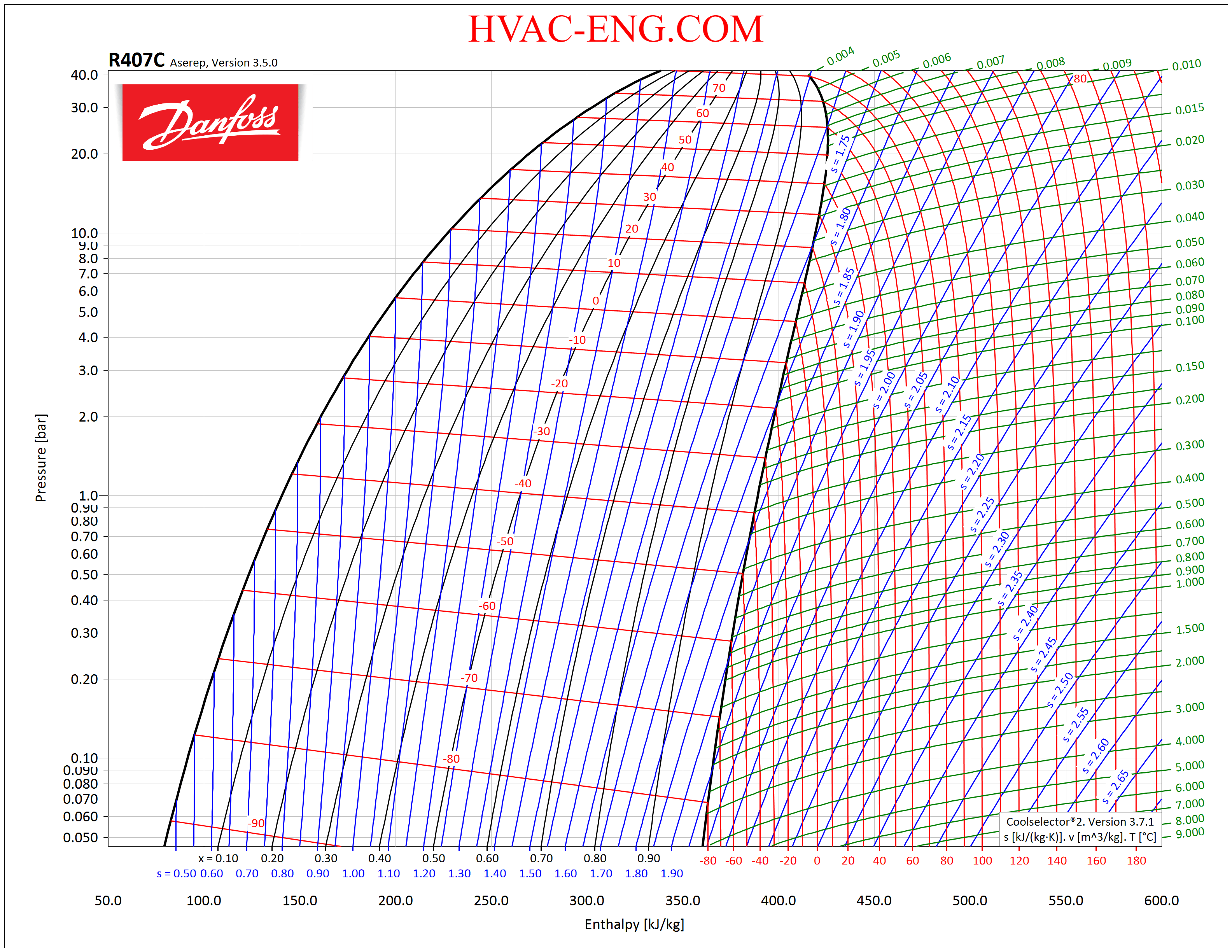

R404A is a mixture of R143a, R125 and R134a (the ratio of the mass fractions of the components is 52, 44 and 4, respectively), and R507 is an azeotropic mixture of R143a (50%) and R125 (50%).

R404A is a near azeotropic refrigerant mixture (temperature glide, i.e., the phase transition temperature difference at constant pressure is approximately 0.6K). For comparison, R507 is an azeotropic mixture (liquid and gas phases have the same composition under thermodynamic equilibrium conditions, there is no glide), which behaves like a one-component liquid. Both refrigerants are suitable for an evaporating temperature range of -45 to + 10 ° C.

The heat transfer coefficient of an azeotropic mixture is generally higher than that of a non-azeotropic mixture. Therefore, a heat exchanger using an azeotropic mixture, all other things being equal, has a smaller heat exchange area or a higher evaporation temperature and a lower condensation temperature, which, in principle, leads to significant energy savings.

Another advantage of the R507 blend is that it does not contain R134a. In fact, the thermodynamic and physical characteristics of R134a not only adversely affect heat transfer, but also lead to a decrease in the volumetric refrigeration capacity of R404A (possibly a 15% reduction), especially at low evaporating temperatures (below −30 ° C).

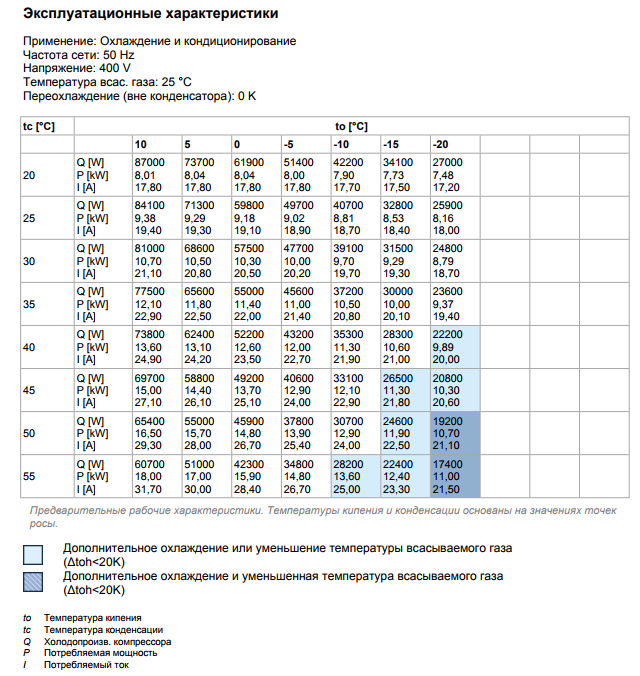

Tests have shown that the R507 refrigerant meets the basic requirement for replacing R502 in modernized systems: the refrigerating capacity of the new refrigerant is the same as that of the replaced one, or even higher. In fact, the refrigerating capacity of R507 in most cases slightly exceeds the refrigerating capacity of R502, while the refrigerating capacity of R404A is the same as that of R502, or slightly lower.

The efficiency of the system on R507 can be higher or lower than the efficiency of the system on R502, depending on the type of system, while the efficiency of the system on R404A is always lower than when using R507 or R502. This was found out by testing various refrigerants for an industrial refrigeration plant that previously used R22 refrigerant. The R507 blend is even more efficient than R502 when the liquid refrigerant is subcooled before entering the control valve.

This was found out by testing various refrigerants for an industrial refrigeration plant that previously used R22 refrigerant. The R507 blend is even more efficient than R502 when the liquid refrigerant is subcooled before entering the control valve.

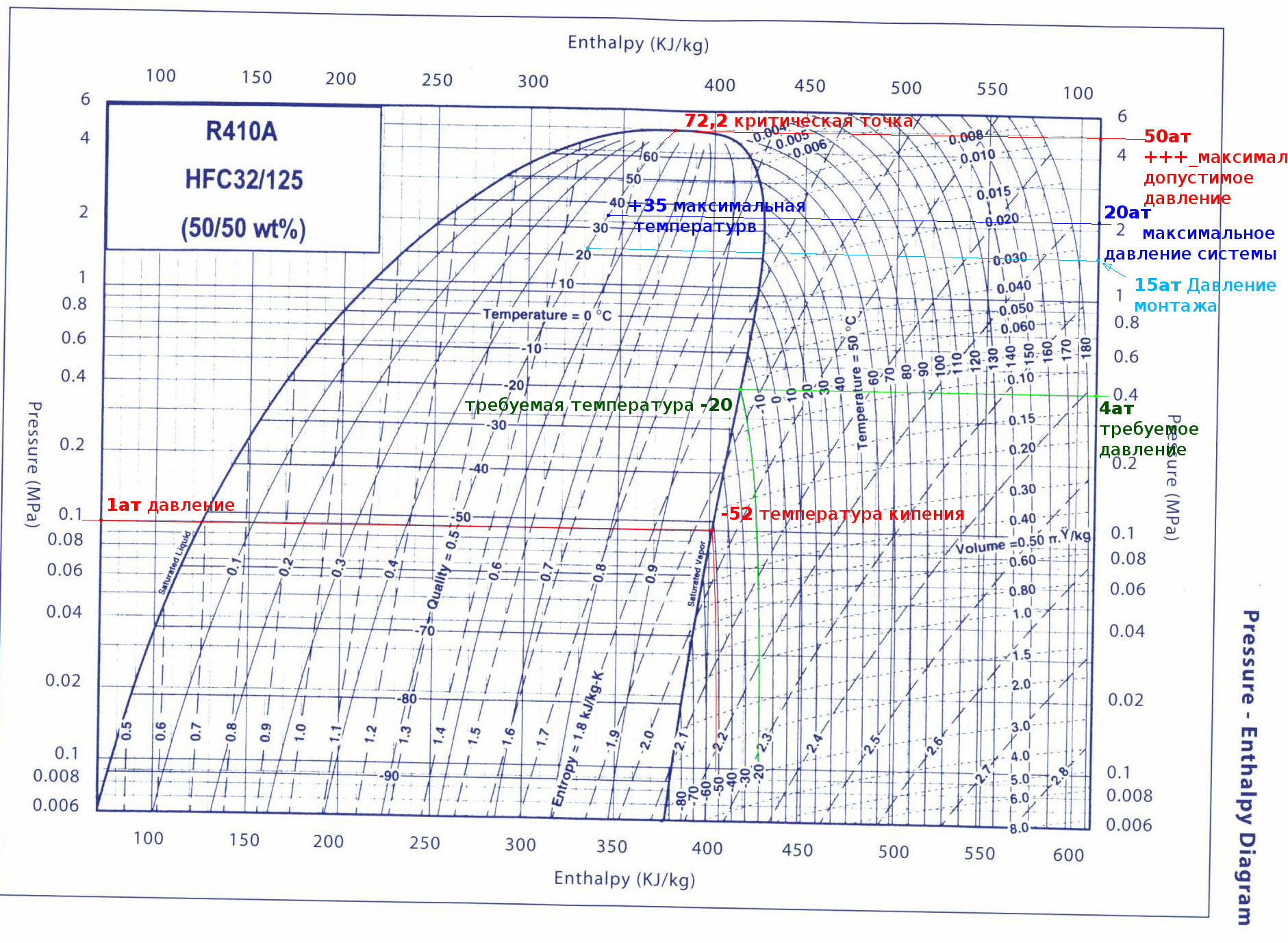

The use of R507 increases the reliability of the compressor, since the discharge temperature in this case is 1-2 ° C lower than for R404A, 11-12 ° C lower than for R502

and even lower for R22.

The use of R507 also allows for a 2% reduction in pressure ratio compared to R404A.

This, together with the higher efficiency of the heat exchangers (especially the condensers), makes it possible to optimize the energy requirements of the compressor and improve the performance.

In the meantime, there is no need to know about it. ”

Maintenance with R404A and R507

R507 is an azeotropic mixture that behaves like a one-component liquid, and therefore, in its application, unlike R404A, there are no problems associated with the separation of components. As a result, when charging, R507 refrigerant can be in both liquid and gaseous form, which allows you to easily restore its shortage after a leak and subsequent repair work.

As a result, when charging, R507 refrigerant can be in both liquid and gaseous form, which allows you to easily restore its shortage after a leak and subsequent repair work.

However, both R507 and R404A can be used in the system as the mixture will still meet specifications even after 50% of the total refrigerant has leaked. In practice, when refueling with R507, the efficiency of the system increases over time.

In most cases, we do not recommend mixing refrigerants, but the combined use of R507 and R404A is quite acceptable and does not lead to any difficulties, since the components of these two refrigerants are almost identical and well compatible.

( in the R404A mixture, R134a is present in the amount of 4 wt %).

The resulting mixture differs little in its characteristics from the original refrigerant.

When replacing R404A with R507, the suction and discharge pressures increase slightly.

In the meantime, there is no need to know about it. ”

In ozrastaet and refrigeration capacity (by 1-3% depending on the type of system used).

Therefore, the use of R507 is especially useful for maintenance .

In addition, replacing R404A with R507 can be a solution in cases where heat exchangers are operated at their limits. This replacement improves the efficiency of the heat exchanger and improves the performance of the compressor.

Both R404A and R507 require synthetic lubricants such as polyester oils. Lubricants for CFC and HCFC refrigerants such as mineral oil and alkylbenzene do not have appreciable solubility in hydrofluorocarbon compounds. This can interfere with the circulation of the oil in the system and make it difficult to return to the compressor.

Use only filter driers recommended for use with R404A or R507. Since synthetic lubricants for these refrigerants absorb moisture more strongly, it is advisable to use a slightly larger filter to increase moisture separation . In any case, it is strongly recommended to follow the rules for handling liquefied gases when servicing systems with refrigerants R404A and R507.

In the meantime, there is no need to know about it. ”

Compliance with regulations

Whichever refrigerant is used in the system, it is imperative to prevent polluting emissions to the atmosphere by implementing good working practices and regularly checking for leaks. Therefore, the work must be carried out by qualified specialists using the appropriate equipment, which will ensure the tightness of the joints. In addition, the design and commissioning of systems should take into account the criteria for optimal efficiency and ease of maintenance (which includes, in particular, regular cleaning of the evaporator and condenser).

Moreover, it is imperative that all used refrigerant is properly disposed of.

In the long term, both R404A and R507 blends have proven to be effective replacements for chlorinated hydrocarbons (CFCs and HCFCs) for both new equipment and retrofit systems that previously used R502 refrigerant.

R404A is the most commonly used and widely used HFC refrigerant. Where energy savings or ease of use are essential, R507 offers some advantages over R404A. With these small but distinct additional benefits, refrigeration owners can reap significant benefits over the long term.

Where energy savings or ease of use are essential, R507 offers some advantages over R404A. With these small but distinct additional benefits, refrigeration owners can reap significant benefits over the long term.

In the meantime, there is no need to know about it. ”

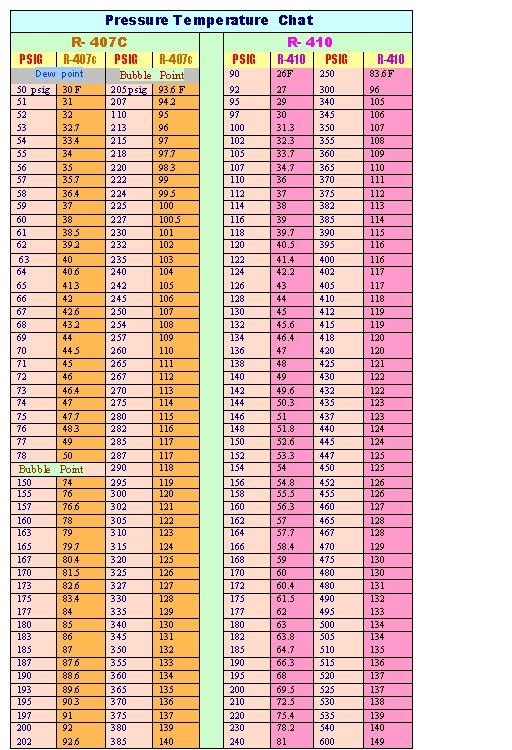

Refrigeration systems in transport equipment use two refrigerants.

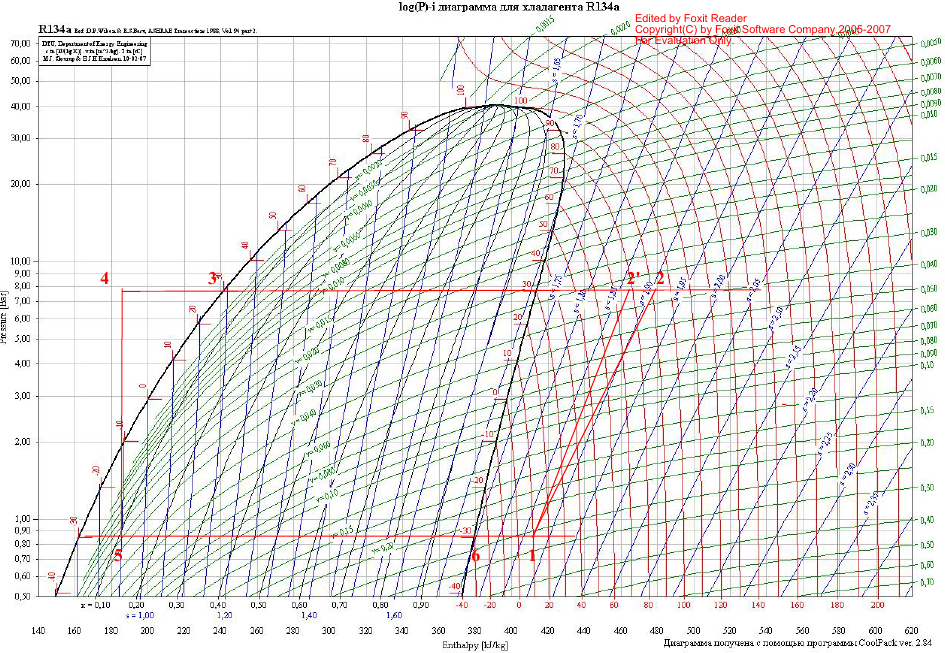

R134a — low pressure refrigerant. Working pressure about 16 atmospheres. It is also used in car and bus air conditioners.

It is a one-component gas and allows any refueling during repairs and refueling.

In the meantime, there is no need to know about it. ”

Refrigerated trucks operating on R134a, unlike those operating on R404a, bring down the temperature inside the van faster, namely by 30%, in the range from +30 to 0 degrees.

Refrigerant R404a is a high pressure mixture. Working pressure about 27 atm .

It is used in all refrigerated trucks operating on heat and for transporting frozen food.

It is a three-component gas and in the event of a leak of more than 30% of the filling volume, a full filling is required during repairs, which increases the cost of its maintenance.

Since the operating pressure of the R404a refrigerant is almost 2 times higher than that of the R134a, therefore, the compressors designed to operate on these refrigerants will be different both in design and in price.

Compressors for R404a have special markings such as HD or XD, and they differ from conventional compressors by the presence of a special Teflon coating on the pistons and special neoprene seals between the compressor casing parts .

If the compressor «born» for R134a is used in systems with R404a, then it is equivalent to pouring A95 gasoline into the engine running on A76 gasoline. The engine will overheat and jam !!!

In the meantime, there is no need to know about it. ”

Call +79885456053

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

R-404A Таблица давления и температуры — HVAC Buddy®

R125/R134a/R143a

Тип масла:ПОЛИОЛЭФИР

Критическая температура: 90 006161,7 F / 72 C

Критическое давление: 540,8 фунтов на кв. дюйм / 37,3 бар

дюйм / 37,3 бар

44/4/52

GWP:3922

900 04 Класс безопасности:A1

Заменить:R22 (R502)

Озоноразрушающий потенциал: Цветовой код:Оранжевый

Молекулярная масса:97,6

Температура кипения:-51,88 F / -46,6 C

| температура °F | температура °F | пузырьки/кв. дюйм абз. 0 | 0,4 | 0,3 |

|---|---|---|---|---|

| -149,0 | 0,4 | 0,4 | ||

| -148,0 | 0,4 | 0,4 | -147,0 | 0,4 | 0,4 |

| -146,0 | 0,5 | 0,4 | — 145,0 | 0,5 | 0,4 |

| -144,0 | 0,5 | 0,5 | ||

| 0,5 | 0,5 | |||

| -142,0 | 0,6 | 0,5 | ||

| -141,0 | 0,6 | 0,5 | ||

| -140,0 | 0. 6 6 | 0,6 | ||

| -139,0 | 0,6 | 0,6 | ||

| -138,0 | 0 .7 | 0,6 | ||

| -137,0 | 0,7 | 0,6 | ||

| -136,0 | 0,7 | 900 83 0,7|||

| -135,0 | 0,8 | 0,7 | ||

| -134,0 | 0,8 | 0,7 | ||

| -133,0 | 0,9 | 0,8 | 900 79||

| -132,0 | 0,9 | 0,8 | ||

| -131,0 | 0,9 | 0,9 | 90 079||

| -130,0 | 1,0 | 0,9 | ||

| -129,0 | 1,0 | 0,9 | ||

| 1,1 | 1,0 | |||

| -127,0 | 1,1 | 1,0 | ||

| -126,0 | 1,2 | 1,1 | ||

| -125,0 9008 4 | 1,2 | 1,1 | ||

| -124,0 | 1,3 | 1,2 | ||

| -123,0 900 84 | 1,3 | 1,2 | ||

| -122,0 | 1,4 | 1,3 | ||

| -121,0 | 1 . 4 4 | 1,3 | ||

| -120,0 | 1,5 | 1,4 | ||

| -119,0 | 1,6 | 1,4 | ||

| -118,0 | 1,6 | 1. 5 | ||

| -117,0 | 1,7 | 1,6 | ||

| -116,0 | 1,8 | 1 .6 | ||

| -115,0 | 1,8 | 1,7 | ||

| -114,0 | 1,9 | 1,8 | 900 79||

| -113,0 | 2,0 | 1,9 | ||

| -112,0 | 2.1 | 1.9 | ||

| -111.0 | 2.2 | 2.0 | ||

| -110. 0 | 2,2 | 2,1 | ||

| -109,0 | 2,3 | 2,2 | ||

| -108 .0 | 2,4 | 2,3 | ||

| -107,0 | 2,5 | 2,3 | ||

| -106,0 | 900 83 2,62,4 | |||

| -105,0 | 2,7 | 2,5 | ||

| -104,0 | 2,8 | 2,6 | ||

| -103,0 | 2,9 | 2. 7 7 | ||

| -102,0 | 3,0 | 2,8 | ||

| -101,0 | 3,1 | 2 .9 | ||

| -100,0 | 3,2 | 3,1 | ||

| -99,0 | 3,4 | 3,2 | 9007 9||

| -98,0 | 3,5 | 3,3 | ||

| -97,0 | 3,6 | 3,4 | ||

| -96,0 | 3,7 | 3,5 | ||

| — 95,0 | 3,9 | 3,7 | ||

| -94,0 | 4,0 | 3,8 | ||

| -9 3.0 | 4,2 | 3,9 | ||

| -92,0 | 4,3 | 4,1 | ||

| -91,0 | 4,4 | 4,2 | ||

| -90,0 | 4,6 | 4,4 | ||

| -89,0 | 4,8 | 4,5 | ||

| -88,0 | 4,9 | 4,7 | ||

| -87,0 | 5,1 | 4,8 | ||

| -86,0 | 5,3 | 5,0 9 0084 | ||

| -85,0 | 5,4 | 5,2 | ||

| -84,0 | 5,6 | 5,3 | ||

| -83,0 | 5,8 | 5,5 | ||

| -82,0 | 6,0 | 5,7 | ||

| -81,0 | 6,2 | 5,9 | ||

| -80,0 | 6,4 | 6,1 | ||

| -79,0 | 6,6 | 6,3 | ||

| -78,0 9 0084 | 6,8 | 6,5 | ||

| -77,0 | 7,0 | 6,7 | ||

| -76,0 | 7,2 | 6,9 | ||

| -75,0 | 7,4 | 7,1 | ||

| -74,0 | 7,7 | 7,3 | ||

| -73,0 | 7,9 | 7,6 | ||

| -72,0 | 8,2 | 7,8 | ||

| -71,0 | 8,4 | 8,0 9 0084 | ||

| -70,0 | 8,7 | 8,3 | ||

| -69,0 | 8,9 | 8,5 | ||

| -68,0 | 9,2 | 8,8 | ||

| -67,0 | 9,5 | 9,1 | ||

| -66,0 | 9,7 | 9,3 | ||

| -65,0 | 10,0 | 9,6 | ||

| -64,0 | 10,3 | 9,9 | ||

| -63,0 | 10,6 | 10,2 | ||

| -62,0 | 10,9 | 10,5 | ||

| -61,0 | 9 0083 11,210,8 | |||

| -60,0 | 11,6 | 11,1 | ||

| -59,0 | 11,9 | 11,4 | ||

| -58,0 | 12,2 90 084 | 11,8 | ||

| -57,0 | 12,6 | 12,1 | ||

| -56,0 | 12,9 | 12,4 | ||

| -55,0 | 13,3 | 12,8 | ||

| -54,0 | 13,6 | 13,1 | ||

| -53,0 | 14,0 | 13,5 | ||

| -52,0 | 14,4 | 13,9 | ||

| -51,0 | 14,8 | 14,3 90 084 | ||

| -50,0 | 15,2 | 14,6 | ||

| -49,0 | 15,6 | 15,0 | ||

| -48,0 | 16,0 | 15,4 | ||

| -47,0 | 16,4 | 15,9 | -46,0 | 16,8 | 16,3 |

| -45,0 | 17,3 | 16,7 | ||

| -44,0 | 17,7 | 17,1 | ||

| -4 3,0 | 18,2 | 17,6 | ||

| -42,0 | 18,7 | 18,1 | ||

| 19,1 | 18,5 | |||

| -40,0 | 19,6 | 19,0 | ||

| -39,0 | 9 0083 20,119,5 | |||

| -38,0 | 20,6 | 20,0 | ||

| -37,0 | 21,1 | 20,5 | ||

| -36,0 | 2 1,7 | 21,0 | ||

| -35,0 | 22,2 | 21,5 | ||

| -34,0 | 9008 3 22,722,1 | |||

| -33,0 | 23,3 | 22,6 | ||

| -32,0 | 23,9 | 9 0083 23,2|||

| -31,0 | 24,4 | 23,7 | ||

| -30,0 | 25,0 | 24,3 | ||

| -29,0 | 25,6 | 2 4,9 | ||

| -28,0 | 26,2 | 25,5 | ||

| -27,0 | 26,9 | 9008 3 26,1|||

| -26,0 | 27,5 | 26,7 | ||

| -25,0 | 28,1 | 27,4 | 9 0079||

| -24,0 | 28,8 | 28,0 | ||

| -23,0 | 29,5 | 28,7 | ||

| -22,0 | 30,1 | 29,3 | -21,0 | 30,8 | 30,0 |

| -20,0 | 31,5 | 30,7 | ||

| — 19,0 | 32,2 | 31,4 | ||

| -18,0 | 33,0 | 32,1 | ||

| 33,7 | 32,9 | |||

| -16,0 | 34,5 | 33,6 | ||

| -15,0 | 35,2 | 34,4 | ||

| -14,0 90 084 | 36,0 | 35,1 | ||

| -13,0 | 36,8 | 35,9 | ||

| -12,0 | 37,6 | 36,7 | ||

| -11,0 | 38,4 | 37,5 | ||

| -10,0 | 39,3 | 38,3 | ||

| -9,0 | 40,1 | 39. 2 2 | ||

| -8,0 | 41,0 | 40,0 | ||

| -7,0 | 41,8 | 40,9 | ||

| -6,0 | 42,7 | 41,7 | ||

| -5,0 | 43,6 | 9008 3 42,6|||

| -4,0 | 44,5 | 43,5 | ||

| -3,0 | 45,5 | 44 .5 | ||

| -2,0 | 46,4 | 45,4 | ||

| -1,0 | 47,4 | 46,3 | ||

| 0,0 | 48,4 | 47,3 | 1,0 | 49,3 | 48,3 |

| 2,0 | 50,4 | 49,3 | 3,0 | 51,4 | 50,3 |

| 4,0 | 52,4 | 51,3 | ||

| 5,0 | 53 .5 | 52,4 | ||

| 6,0 | 54,5 | 53,4 | ||

| 7,0 | 55,6 | 54,5 | ||

| 8,0 | 56,7 9008 4 | 55,6 | ||

| 9,0 | 57,8 | 56,7 | ||

| 10,0 | 59,0 90 084 | 57,8 | ||

| 11,0 | 60,1 | 59,0 | ||

| 12,0 | 61,3 | 60,1 | ||

| 62,5 | 61,3 | |||

| 14,0 | 63,7 | 62,5 | ||

| 15,0 | 64,9 | 63,7 | 16,0 | 66,2 | 64,9 |

| 17,0 | 67,4 | 66,2 | ||

| 18,0 | 68,7 | 67,4 | ||

| 19,0 | 70,0 | 68,7 | ||

| 20,0 | 71,3 9 0084 | 70,0 | ||

| 21,0 | 72,6 | 71,3 | ||

| 22,0 | 74,0 | 72,7 | ||

| 23,0 | 7 5,3 | 74,0 | ||

| 24,0 | 76,7 | 75,4 | ||

| 25,0 | 9008 3 78,176,8 | |||

| 26,0 | 79,5 | 78,2 | ||

| 27,0 | 81,0 | 79,6 | 28,0 | 82,4 | 81,1 |

| 29,0 | 83,9 | 82,5 | ||

| 30,0 | 85,4 | 84,0 90 084 | ||

| 31,0 | 87,0 | 85,5 | ||

| 32,0 | 88,5 | 87,1 | ||

| 33,0 | 90,1 | 88,6 | ||

| 34,0 | 91,6 | 90,2 | ||

| 35,0 | 9 0083 93,391,8 | |||

| 36,0 | 94,9 | 93,4 | ||

| 37,0 | 96,5 | 95,0 | ||

| 3 8,0 | 98,2 | 96,7 | ||

| 39,0 | 99,9 | 98,4 | ||

| 101,6 | 100,1 | |||

| 41,0 | 103,3 | 101,8 | ||

| 42,0 | 105,1 | 900 83 103,5|||

| 43,0 | 106,9 | 105,3 | ||

| 44,0 | 108,7 | 107,1 | ||

| 45,0 | 9008 3 110,5108,9 | |||

| 46,0 | 112,3 | 110,7 | ||

| 47,0 900 84 | 114,2 | 112,6 | ||

| 48,0 | 116,1 | 114,5 | ||

| 49,0 | 118,0 | 116,4 | 900 79||

| 50,0 | 120,0 | 118,3 | ||

| 51,0 | 121,9 | 120,3 | ||

| 52,0 | 123,9 | 9008 3 122,2|||

| 53,0 | 125,9 | 124,2 | ||

| 54,0 | 128,0 900 84 | 126,3 | ||

| 55,0 | 130,0 | 128,3 | ||

| 56,0 | 132,1 | 130,4 | ||

57 . 0 0 | 134,2 | 132,5 | ||

| 58,0 | 136,3 | 134,6 | ||

| 59,0 | 138,5 | 136,8 900 84 | ||

| 60,0 | 140,7 | 138,9 | ||

| 61,0 | 142,9 | 14 1,1 | ||

| 62,0 | 145,2 | 143,4 | ||

| 63,0 | 147,4 | 145,6 | ||

| 64,0 | 900 83 149,7147,9 | |||

| 65,0 | 152,0 | 150,2 | ||

| 66,0 | 154,4 | 152,5 | ||

| 156,7 | 154,9 | |||

| 68,0 | 159,1 | 157,3 | 69,0 | 161,6 | 159,7 |

| 70,0 | 164,0 | 162,1 | ||

| 71,0 | 166,5 | 900 83 164,6|||

| 72,0 | 169.0 | 167,1 | ||

| 73,0 | 171,5 | 169,6 | ||

| 74,0 | 174,1 | 172,2 | ||

| 75,0 | 176,7 | 174,8 | ||

| 76,0 | 179,3 | 177,4 | ||

| 77,0 | 182,0 | 180,0 | ||

| 78,0 | 184,6 | 182 . 7 7 | ||

| 79,0 | 187,3 | 185,4 | ||

| 80,0 | 190,1 | 188,1 | ||

| 81,0 | 192. 9 | 190,9 | ||

| 82,0 | 195,7 | 193,7 | ||

| 83,0 | 900 83 198,5196,5 | |||

| 84,0 | 201,3 | 199,3 | ||

| 85,0 | 204,2 | 202,2 | 86,0 | 207,2 | 205,1 |

| 87,0 | 210,1 | 208,1 | ||

| 88,0 | 213,1 | 9008 3 211,1|||

| 89,0 | 216,1 | 214,1 | ||

| 90,0 | 219,2 900 84 | 217,1 | ||

| 91,0 | 222,3 | 220,2 | ||

| 92,0 | 225,4 | 223,3 | ||

| 93 .0 | 228,5 | 226,4 | ||

| 94,0 | 231,7 | 229,6 | ||

| 95,0 | 234,9 | 232,8 900 84 | ||

| 96,0 | 238,1 | 236,0 | ||

| 97,0 | 241,4 | 23 9,3 | ||

| 98,0 | 244,7 | 242,6 | ||

| 99,0 | 248,1 | 246,0 | ||

| 100,0 | 90 083 251,5249,3 | |||

| 101,0 | 254,9 | 252,8 | ||

| 102,0 | 258,3 | 256,2 | 90 079||

| 103,0 | 261,8 | 259,7 | ||

| 104,0 | 265,3 | 263,2 | ||

| 105,0 | 268,9 | 2 76,1274,0 | ||

| 108,0 | 279,8 | 277,6 | ||

| 109,0 | 283,5 | 281,3 | ||

| 287,2 | 285,1 | |||

| 111,0 | 291,0 | 288,8 | ||

| 112,0 | 294,8 | 292,7 | ||

| 113,0 | 298,7 | 296,5 | ||

| 114,0 | 302,6 | 9 0083 300,4|||

| 115,0 | 306,5 | 304,3 | ||

| 116,0 | 310,5 | 308,3 | ||

| 11 7,0 | 314,5 | 312,3 | ||

| 118,0 | 318,5 | 316,4 | ||

| 119,0 | 322,6 | 320,4 | ||

| 120,0 | 326,8 | 324,6 | ||

| 121,0 | 330,9 | 3 28,8 | ||

| 122,0 | 335,1 | 333,0 | ||

| 123,0 | 339,4 | 337,2 | ||

| 124,0 | 90 083 343,7341,5 | |||

| 125,0 | 348,0 | 345,9 | ||

| 126,0 | 352,4 | 350,2 | ||

| 127,0 | 356,8 | 354,7 | ||

| 128,0 | 361,3 | 359,1 | 9 0079||

| 129,0 | 365,8 | 363,7 | ||

| 130,0 | 370,3 | 368,2 | ||

| 131,0 | 37 4,9 | 372,8 | ||

| 132,0 | 379,6 | 377,5 | ||

| 133,0 | 384,3 | 382,2 | ||

| 134,0 | 389,0 | 386,9 | ||

| 135,0 | 393,8 | 391,7 | 136,0 | 398,6 | 396,6 |

| 137,0 | 403,5 | 401,4 | ||

| 138,0 | 408,4 900 84 | 406,4 | ||

| 139,0 | 413,4 | 411,4 | ||

| 140,0 | 418,4 | 416,4 | ||

| 141,0 | 423,5 | 421,5 | ||

| 142,0 | 428,6 | 426,6 | ||

| 433,8 | 431,8 | |||

| 144,0 | 439,0 | 437,1 | ||

| 145,0 | 444,3 | 90 083 442,4|||

| 146,0 | 449,6 | 447,8 | ||

| 147,0 | 455,0 | 453,2 | ||

| 148,0 | 1 50,0471,5 | 469,8 | 948 1.||

| 153,0 | 488,5 | 486,9 | ||

| 154,0 | 494,3 | 492,8 | ||

| 155,0 | 500,2 | 498,7 | ||

| 156,0 | 506,1 | 504,7 | ||

| 157,0 9 0084 | 512,1 | 510,8 | ||

| 158,0 | 518,1 | 516,9 | ||

| 159,0 | 524,3 | 523,2 9 0084 | ||

| 160.0 | 530.5 | 529.5 |

HVAC Buddy®

Упростите свою работу с помощью нашего удобного рефрижератора герант зарядка и диагностика Приложение HVAC.

HVAC Buddy®

Облегчите себе работу с помощью нашего удобного хладагента Давление Температура Приложение HVAC.

Каким должно быть давление для 404A? – БиоСидмартин

Разное

Эстер Флеминг

Каким должно быть давление для 404A?

Таблица давления хладагента R404a

| Температура (по Фаренгейту) | Температура (по Цельсию) | R404a Давление |

|---|---|---|

| – 35°F | – 37,2°С | 6,8 фунтов на кв. дюйм дюйм |

| – 30°F | – 34,4°С | 9,6 фунтов на кв. дюйм |

| – 25°F | – 31,7°С | 12,7 фунтов на кв. дюйм |

| – 20°F | – 28,9°С | 16 фунтов на кв. дюйм |

Как заправлять фреоном r404?

Баллоны с хладагентом R-404A и R-507 имеют погружную трубку, и жидкость заправляется при вертикальном положении баллона. Прервите окончательный вакуум, заправив жидкий хладагент в отверстие выпускного клапана ресивера или в область жидкостной линии ниже по потоку от выхода ресивера.

Как рассчитать заправку хладагента?

Никаких сложных математических расчетов не требуется, вы просто суммируете газ в трубе, секцию компрессора/конденсатора и испаритель = общий заряд. В результате они захватывают только 30-40% заряда системы и, следовательно, не учитывают плату за емкость.

Каким должно быть давление на стороне высокого и низкого давления?

Фактические показания зависят от температуры окружающей среды. Низкая сторона должна быть около 30 фунтов на квадратный дюйм при 90 градусах по Фаренгейту или меньше. Давление, которое слишком сильно ниже или выше, указывает на наличие проблемы. В правильно работающей системе давление на стороне высокого давления будет примерно в два раза выше температуры окружающей среды плюс 50 фунтов на квадратный дюйм.

Низкая сторона должна быть около 30 фунтов на квадратный дюйм при 90 градусах по Фаренгейту или меньше. Давление, которое слишком сильно ниже или выше, указывает на наличие проблемы. В правильно работающей системе давление на стороне высокого давления будет примерно в два раза выше температуры окружающей среды плюс 50 фунтов на квадратный дюйм.

Можно ли заряжать 404A как газ?

Из-за почти азеотропной природы Forane® 404A лучше заправлять его в жидком виде, чтобы предотвратить фракционирование (изменения в расчетном составе хладагента), но его также можно заправлять в виде газа.

Какое количество хладагента следует заправлять?

Общее практическое правило Общее количество, которое можно рассчитать, составляет 2-4 фунта на тонну охлаждения для вашей системы. Например: 3-тонному кондиционеру или тепловому насосу с 35-футовым трубопроводом потребуется в общей сложности примерно 6-12 фунтов хладагента для полной перезарядки из пустого. Это включает в себя набор линий, катушку и блок.

1

1